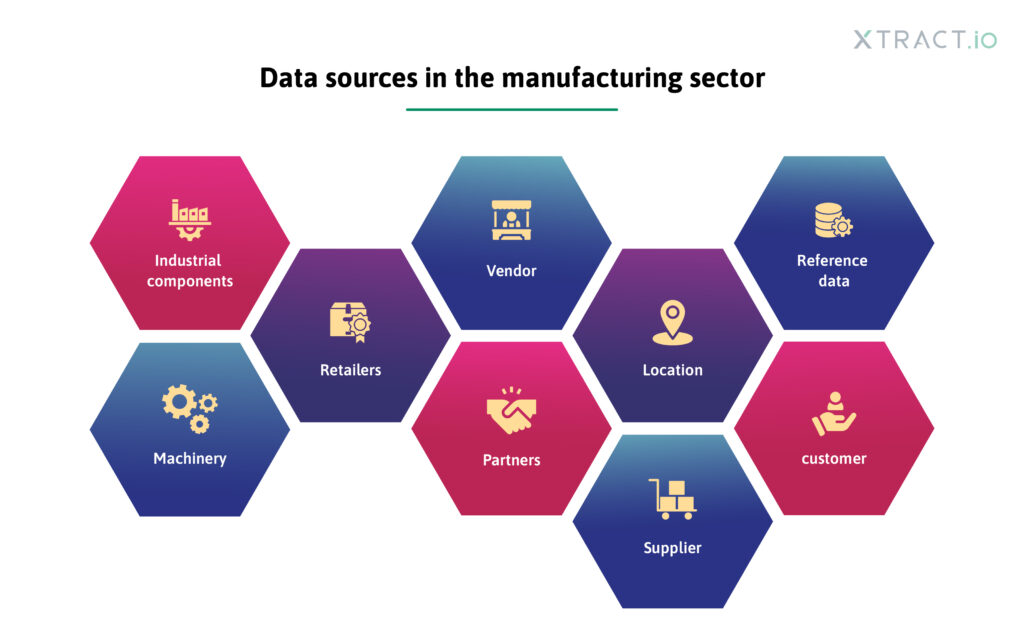

The increasing adoption of digital technologies such as Industrial IoT, cloud computing, artificial intelligence, and machine learning has led to a massive influx of data from different manufacturing processes. To leverage the full potential of this data, manufacturers must have robust data management solutions in place. Data management solutions can help manufacturers to collect, process, store, and analyze large volumes of data in real time, enabling them to gain valuable insights into their operations, improve process efficiency, and enhance the overall quality of their products.

In this blog post, we’ll explore how data management solutions can transform the manufacturing industry and the key benefits they offer manufacturers.

The data dilemma in the manufacturing sector

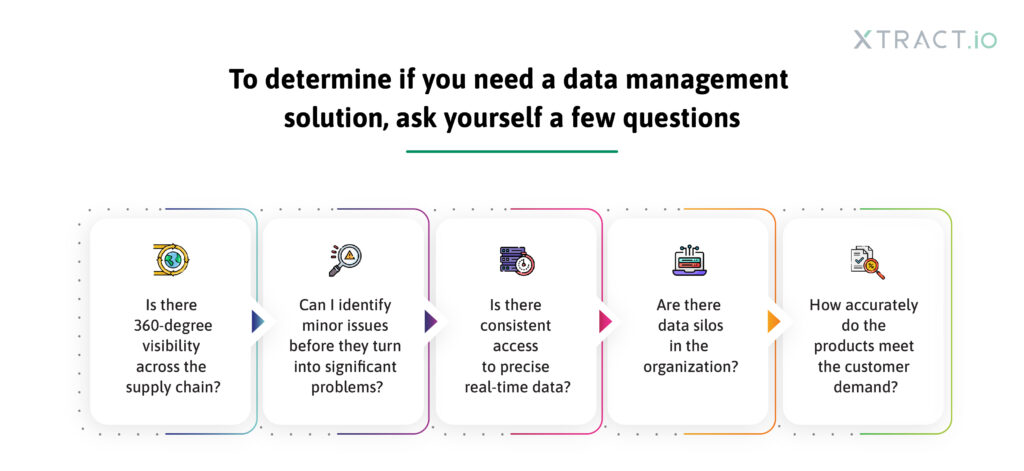

According to the World Economic Forum, effectively using data can help manufacturers become more sustainable, from reducing waste to optimizing energy consumption. However, many manufacturers struggle to leverage data effectively despite the potential benefits. Data silos are one of the main causes of this challenge. Vital information is often distributed across numerous systems, resulting in a skewed perspective of the production process, making it harder to spot trends and chances for improvement.

Data silos not only hinder the ability of manufacturers to become sustainable but also impact the quality of an organization’s production. At Xtract.io, we have developed an AI-powered data management solution that automates data extraction, processing, and integration and effectively improves manufacturing processes.

Unlock new opportunities for growth and value

Effective data management in manufacturing goes beyond collecting and storing data; it can address all of the industry’s challenges and accelerate digital transformation. Manufacturers can streamline operations, optimize processes, and drive innovation by leveraging data management solutions.

Here are some of the critical use cases for data management in the manufacturing industry:

Inventory management

Inventory management can be difficult, especially when you have several SKUs and unpredictable demand. Data management solutions can streamline inventory management by providing real-time visibility into inventory levels, supplier performance, and delivery schedules. This data helps businesses optimize inventory levels, reducing the risk of stockouts while minimizing the cost of holding excess inventory.

Automating repetitive tasks and reducing errors is another benefit of data management in inventory management. Manufacturers can automate production when inventory levels hit a threshold, ensuring they always have enough stock to fulfill client demand.

Predictive maintenance

Unplanned downtime due to equipment failure can be costly and disruptive in manufacturing. Predictive maintenance, which involves analyzing data from sensors and equipment to identify potential problems before they occur, can help businesses reduce downtime and extend the life of their equipment. However, the best data management is necessary to implement a predictive maintenance program in the industry.

Businesses can identify patterns and trends that may indicate an impending equipment failure by collecting and analyzing data from various sources, including sensors, maintenance records, and historical performance data. With this information, maintenance teams can proactively address the issue before it leads to downtime or costly repairs while reducing the likelihood of defects in the final product.

Customer satisfaction

Businesses can acquire significant insights into customers’ desires and requirements by analyzing their behavior, preferences, and feedback. This information can be utilized to personalize products and services to particular client needs, improving the overall customer experience.

Effective customer data management solutions can help you tailor products, services, and marketing campaigns to meet individual customers’ unique needs and preferences. Analyzing customer behavior, preferences, and feedback can help anticipate customer needs, optimize their products, and maximize ROI. For example, if a business notices that a customer frequently purchases a specific product, it can offer promotions or discounts on that product to increase customer satisfaction and loyalty.

Final thoughts

Data management is vital in the manufacturing sector, from identifying patterns, trends, and anomalies to accelerating innovation, improving efficiency, and reducing costs. At Xtract.io, we provide a comprehensive data management solution tailored to the industrial industry.

Our data management solution is intended to assist businesses in dealing with the massive amounts of data generated in today’s digital industrial landscape. You can use our technology to streamline data management procedures, lowering the chance of errors and maintaining data accuracy while enabling your team to focus on other vital tasks like product creation and innovation. Connect with us today and modernize how you deal with data.

Related data management blogs

The 5 best practices for customer data management in 2023

Emerging trends of data management in 2023